In today’s fast paced world, technology is at the forefront of innovation across industries, from telecommunications and automotive engineering to electronics and aerospace. With increasing reliance on complex electrical systems, ensuring that cables and wires are protected against environmental stressors has become critical. Among the wide variety of cable protection solutions available, Tech Flex Heat Resistant products have emerged as a leading choice for those seeking superior durability, flexibility, and heat resistance. This article explores what Tech Flex is, its benefits, applications, and how it can safeguard cables in demanding environments.

If you want to know more about Scholarships for Fall 2024 at Chattahoochee Technical College then checkout our last blog post.

What Is Tech Flex?

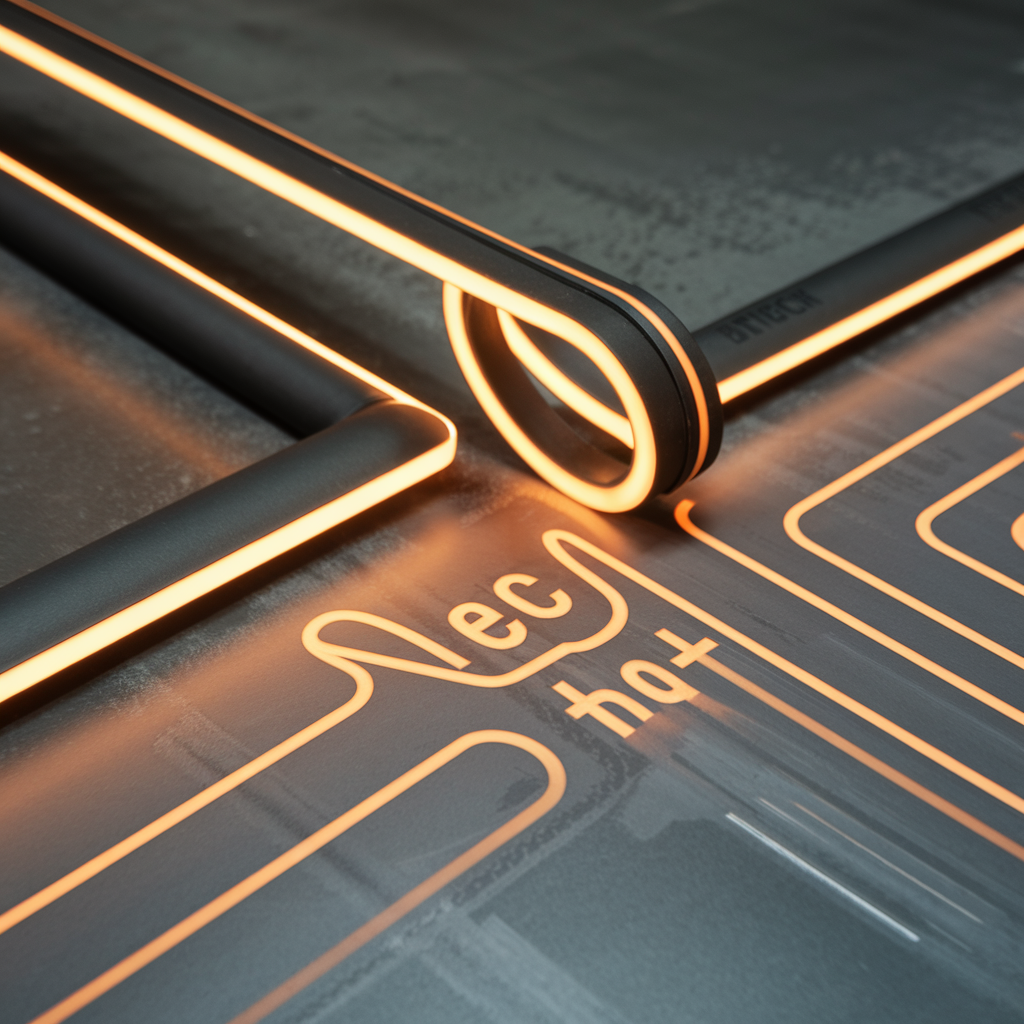

Tech Flex is a brand name that has become synonymous. With high performance protective sleeving used primarily to safeguard cables, wires, and hoses. This flexible material is designed to provide superior protection against a variety of environmental hazards. Such as abrasion, heat, and chemicals, while also offering a professional, clean aesthetic. Tech Flex sleeving is often used in industries where cables are exposed to rigorous conditions. Including high temperatures, mechanical stress, and abrasion.

Heat Resistance. A Critical Feature

One of the standout features of Tech Flex is its heat resistance. In many industrial and consumer applications, cables and wires are subjected to extreme temperatures that can cause damage to the insulation and, ultimately, the system itself. Whether it’s high temperatures in automotive engines, electrical systems, or machinery, cables must be protected from thermal degradation to ensure optimal performance and longevity.

Tech Flex Heat Resistant sleeving is engineered specifically to withstand high temperatures, offering protection even in environments where heat is a constant threat. The sleeving is typically made from materials such as braided fiberglass or expandable PET (polyethylene terephthalate). Which are known for their ability to withstand intense heat without compromising the integrity of the cable or wire within.

The Science Behind Tech Flex Heat Resistance

Tech Flex’s heat resistant products are crafted using a variety of heat-resistant fibers, each offering a unique set of advantages. The materials commonly used in Tech Flex heat-resistant sleeving include.

- Fiberglass: Known for its excellent thermal insulation properties, fiberglass is one of the most commonly used materials for heat resistant cable protection. It can tolerate high temperatures up to 1000°F (537°C) or more, making it ideal for automotive, aerospace, and industrial applications.

- Silicone Coatings: Some Tech Flex products are coated with silicone to enhance their thermal properties. Silicone is an excellent insulator that can handle extreme temperature fluctuations while also offering flexibility and resistance to UV light and moisture. This makes it an excellent option for applications in harsh outdoor conditions.

- Aramid (Kevlar): Aramid fibers, such as Kevlar, are often used in cable protection products that require resistance to both high heat and mechanical stress. Kevlar sleeving is known for its ability to withstand high temperatures up to 900°F (482°C). Making it ideal for use in areas where cables are exposed to fire hazards or intense heat.

- PET (Polyethylene Terephthalate): Although PET is not inherently heat resistant at the levels of fiberglass or aramid. It can withstand moderate heat (up to 266°F or 130°C) and provides an excellent balance of flexibility and protection against wear and tear. This makes it a popular choice for applications where moderate heat resistance is required. Such as in electronics, data centers, and vehicles.

The combination of these materials allows Tech Flex to offer a wide range of heat resistant products designed to meet the specific needs of various industries.

Key Benefits of Tech Flex Heat Resistant Products

- Superior Heat Protection: Tech Flex heat resistant sleeving is designed to protect cables and wires from thermal damage in high temperature environments. This is essential for preventing electrical failures, insulation degradation, or even fires due to overheating.

- Durability: In addition to heat protection, Tech Flex is highly durable. The sleeving material is resistant to abrasion, impact, and general wear and tear, making it ideal for industries. Where cables are exposed to harsh conditions. For example, automotive engines or industrial machinery may subject cables to mechanical stress, and Tech Flex ensures. That the cables remain intact despite these challenges.

- Flexibility: One of the unique selling points of Tech Flex is its flexibility. Unlike rigid cable protectors, Tech Flex sleeving can bend and flex without cracking or losing its protective properties. This makes it a versatile solution for a variety of complex, tight, or irregular installations.

- Chemical and Abrasion Resistance: Many Tech Flex products are also resistant to chemicals and abrasives, further enhancing their performance in industrial environments. Where cables are exposed to oils, solvents, and other harmful substances. This makes Tech Flex a popular choice in automotive, aerospace, and manufacturing sectors.

- Aesthetic Appeal: While functionality is key, aesthetics also play an important role in many applications, particularly in high end electronics and automotive industries. Tech Flex sleeving offers a clean, professional, and organized look. Which is why it is often chosen to improve the visual appeal of complex cable systems. Available in a range of colors and finishes, it enhances both the aesthetics and practicality of the installation.

If you want to know more about Scholarships for Fall 2024 at Chattahoochee Technical College then checkout our last blog post.

Common Applications of Tech Flex Heat Resistant Sleeving

Tech Flex heat resistant products find use in a variety of demanding sectors, where protecting cables from extreme conditions is essential. Some of the most common applications include.

1. Automotive Industry

Automotive engineers face the challenge of protecting wiring systems in environments where heat levels can fluctuate drastically. Under the hood of a car, temperatures can soar as high as 400°F (204°C), especially near the engine or exhaust systems. Tech Flex heat resistant offers a reliable solution by providing protection to wiring and cables from the high heat environment. Whether used to protect ignition cables, sensors, or fuel lines. Tech Flex ensures that cables stay intact, reducing the risk of electrical failures and potential fire hazards.

2. Aerospace and Aviation

In the aerospace industry, safety is paramount, and ensuring the reliability of electrical systems is critical. Aircraft are subject to a wide range of environmental challenges, including extreme temperatures, vibration, and pressure changes. Tech Flex heat resistant products provide protection for critical wiring and electronic systems in airplanes. From the cockpit to the wings, ensuring that cables remain insulated and functional even under the most extreme conditions.

3. Industrial Machinery

Industrial machinery often operates in environments with fluctuating temperatures, intense friction, and chemical exposure. Tech Flex is widely used in manufacturing plants, robotics, and other industrial settings to safeguard cables from the harsh conditions they face. Whether it’s machinery wiring, hydraulic systems, or power cables, Tech Flex ensures the long term durability of the system.

4. Electronics

In the electronics industry, components such as circuit boards, power supplies, and connectors require heat resistant protection. Tech Flex’s heat resistant sleeving is often used in data centers, server rooms, and other electronics heavy environments to keep cables protected from both heat and mechanical damage. It’s especially crucial for high performance systems like computers, telecommunications equipment, and networking devices, where overheating can lead to costly failures.

5. Marine Applications

For vessels operating in marine environments. The combination of moisture and high heat can be a lethal threat to cables and wiring systems. Tech Flex heat resistant sleeving is a preferred option for protecting cables in marine engines, electrical systems, and control panels, as it is both heat and water resistant.

If you want to know more about Scholarships for Fall 2024 at Chattahoochee Technical College then checkout our last blog post.

Conclusion

In an era where cable systems are becoming increasingly complex and integral to the smooth operation of everything from cars to communication satellites. The importance of effective protection cannot be overstated. Tech Flex Heat Resistant products offer a versatile, durable, and flexible solution. To safeguarding cables in environments exposed to extreme temperatures, mechanical stress, and environmental hazards.

Whether you are an engineer in the automotive, aerospace, or electronics industry. Tech Flex provides a reliable means of ensuring that your wiring systems remain protected and functional. With its combination of heat resistance, durability, and aesthetic appeal. Tech Flex is quickly becoming the go to choice for professionals who demand high quality cable protection that stands the test of time.

Pingback: Exploring the Art of Glass Painting: